Data Preparation for 3D Car Configurator: Enhancing Automotive Customization

- hinniemassoda

- Dec 14, 2023

- 3 min read

Updated: Oct 3, 2024

Data preparation is a crucial step in guaranteeing the quality, accuracy and relevance of 3D data. To better understand the importance of this stage, we interviewed our Data Manager, who shared with us the Data Preparation process for the LS CAR project.

Why 3D Car Configurators are Revolutionizing the Automotive Industry

At the moment, in our sector, customers are looking for tools to automate their processes while preserving quality. However, automation doesn't always meet the most stringent quality requirements, especially when it comes to 3D data.

Our main challenge lies in the fact that customers have different levels of digital maturity: some need support in structuring their data.

For their part, customers are looking to exploit various sources of data, going beyond simple 3D data, for a variety of uses such as marketing and industrial use. The harmonisation of this technical, material and marketing data is essential to link the design, production and marketing of products, requiring precise management to guarantee the efficiency of the process.

The Role of Data in Optimizing 3D Car Configurators

The 3D data we process comes from a variety of media, each with its own specific format. Information such as material and finish can be integrated directly into the 3D file or separated out and stored in an Excel file or PDF. When this information is correctly coded, it can be automatically associated with the corresponding objects in software, speeding up data preparation. However, some customers supply files that cannot be automated, such as PDFs or PowerPoint presentations, requiring manual reading and the creation of customised tools to integrate this data. The data format therefore depends on the customer and varies from case to case.

Some customers are very mature about the process and prepare everything upstream: everything will be codified in tables, with a host of references that can be read automatically.

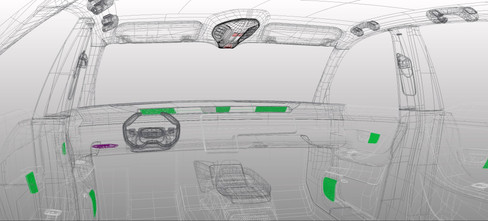

Example of CAD data from LS CAR processed with Pixyz

How was 3D data processed for the LS CAR?

First of all, the vehicle was designed by Technicon Design. Technicon supplied us with CAD data. We then processed it to make it usable on the final support.

Data preparation depends on the use case: whether it's CGI rendering, a real-time application, virtual reality or WebGL. Depending on these needs, we adapt the data in terms of quality and use various optimisation tools to meet these specific requirements.

We carried out two preparations in parallel, each with a specific objective:

The first was to produce very high quality content for the catalogue.

The second was dedicated to the website (WebGL), with more optimised data. Here, we also had to work on optimising the 3D files to reduce their file size. Because on the website, the heavier your file, the longer it will take to load.

What are the advantages of receiving data in CAD format rather than Mesh from Technicon?

CAD data is based on mathematical curves. In other words, they represent perfect shapes made up of perfect lines. When we have CAD data, we have optimum precision. We define an entry point and an exit point, and the curves generated are perfect, with no loss of quality.

Meshes, on the other hand, are approximations of these perfect shapes. They are made up of triangles, each triangle being formed by three points. The higher the quality of the Mesh, the closer it is to the perfect mathematical curve, but it is still slightly degraded in terms of quality compared to CAD data. Our preference for data in CAD format lies in the mastery of data optimisation. As mentioned earlier, CAD data is mathematically perfect and does not suffer any degradation. You get exactly what was designed. Mesh, on the other hand, is a fixed representation based on states, which is not as accurate.

When we receive data in CAD format, we have total control over the quality and quantity of information. On the other hand, if the customer has not prepared the meshes correctly, we may not have enough information to obtain a quality rendering. Conversely, if the meshes contain too much information, we would have to degrade them to reduce the number of triangles, which could affect the quality of the result.

In short, favouring data in CAD format allows us to retain control over quality and optimisation, giving us a more reliable and flexible solution.

What were the most challenging aspects of the LS CAR project?

On the LS CAR project, one of the most complex aspects was adapting to various end media, such as high quality images and webGL, by creating appropriate data to ensure efficient rendering. In addition, creating structured databases for the computer graphics designers was an essential, albeit sometimes time-consuming, step in facilitating their work.